Promoting Sustainable Innovation

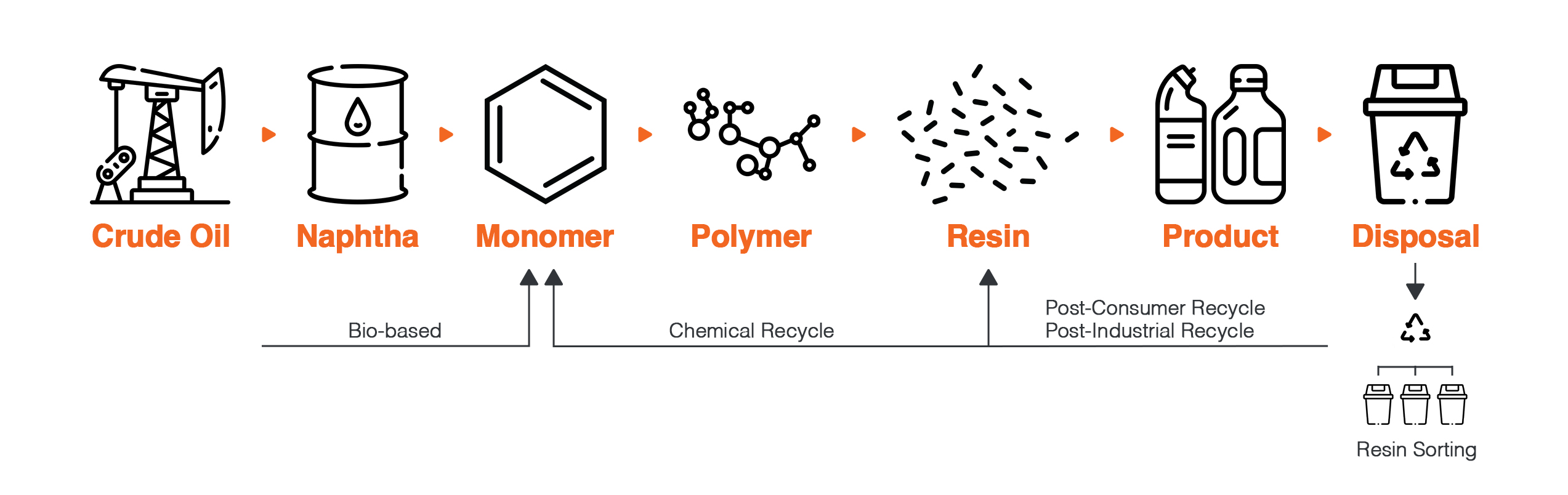

The umbrella phrase that is “Sustainable Plastics” is often misused, misunderstood or misinterpreted. Different end users seek to meet their objectives in providing the most responsible options to their customer available. These brand owners may choose to seek bio-based polymers, materials sourced from post-consumer recycled content, or solutions that offer a lower total carbon footprint through a third party life cycle analysis (LCA). Regardless of the path they choose, Conventus Polymers is committed to offering transparency towards the options in a product portfolio that brings value to meeting brand owner’s sustainability objectives.

Conventus Commitment

At Conventus, our commitment to sustainability goes beyond simply recycling our materials and minimizing our impact. We believe in not just what we are manufacturing, but how we are manufacturing it.

Sustainable Product Portfolio

Conventus provides a full eco-friendly product portfolio that helps customers develop new applications for a circular economy.

Download Our Sustainability Flyer

| Sustainability Initiative | Resin |

|---|---|

| Bio-Based | PBT, PC, PA, PA 12, Amorphous PA, PEI, TPU |

| Chemical Recycle | PC, PC/ABS, PBT, PET/PBT |

| Post-Consumer Recycle | PC, PC/ABS, PBT/PET, ABS |

| Post-Industrial Recycle | ABS, PC, PC/ABS, PA, PP, PBT, HIPS |

| Life Cycle Analysis Improvement | POK, Bio-Mass Balanced ETPs |

| Potential to Compost | PHA, PLA, PBAT, PHBH, PBS |

Conventus Products

Bio-Based Materials

Bio-based bioplastics often generate fewer carbon emissions over their life cycle compared to traditional plastics. A product is considered bio-based if it is made whole or in part from renewable, non-fossil (plant-based) resources such as sugarcane, corn, algae, grasses, or trees.

- SABIC Polycarbonate Copolymer technologies

- Partially bio-based PBT

- Partially bio-based PC

- Bio-based PC – glucose based aliphatic PC copolymers

- Bio-based amorphous PA12

- Bio-based PEI

- Bio-based TPU

Chemical Recycling

Chemical recycling is any process by which a polymer is chemically reduced to its original form so that it can be processed and remade into new plastic materials that go on to be new plastic products. Chemical recycling helps overcome the limits of traditional recycling. It also helps manufacturers continue to push the boundaries of how, and where, recycled plastics can be used.

- UL listed PC, ABS, PC/ABS

- PC, PC/ABS, PBT

- PET/PBT

Post-Consumer Recycling

Post-consumer recycled content (PCR) is content created by consumers after a product has reached the end of its use. These materials are diverted from the landfill and utilized in the production of other commodities. Post-consumer products are made by manufacturers that rely on this waste-diverted material for the creation of new products.

- PC up to 85% PCR (up to 60% with UL)

- PC/ABS up to 60% PCR

- PBT/PET up to 30% PCR

- ABS up to 100% PCR

Post-Industrial Recycling

Post-industrial recycling is a product composition that contains some percentage of manufacturing waste material that has been reclaimed from a process generating the same or a similar product. In the plastics industry recycled material can go into a wide variety of parts that can go through the conversion process and come out as high quality parts.

- ABS, PC, PC/ABS, PA, PP, PBT, and HIPS can be made from post-industrial recycling

Life Cycle Analysis Improvement / CO2 Footprint Reduction

Life cycle assessment (LCA) is a methodology for assessing the environmental impact associated with all the stages of the life cycle of a product. The environmental impacts are assessed from raw material extraction and processing, through the product’s manufacture, distribution and use, to the recycling or final disposal of the materials composing it. Reducing carbon emissions from plastics requires the use of technology including renewable energy, biodegradable plastics, and recycling.

- POK made from methane waste gas

- CO2 footprint – Bio-mass balanced PC, ABS, PC/ABS and PA solutions