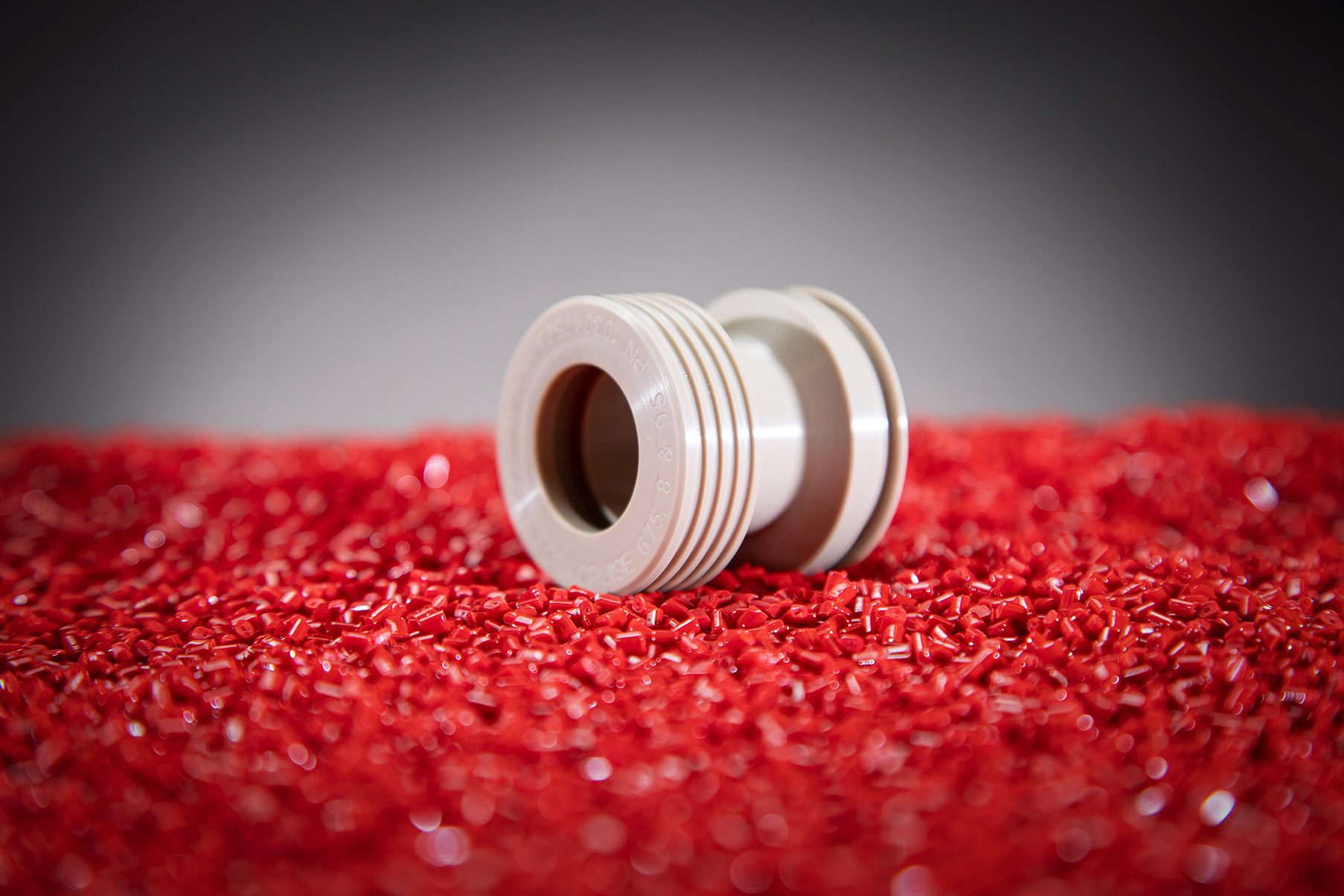

Maximize Oil & Gas Production with High-Quality Polymers

Businesses in the oil and gas industry know that their equipment is up to the task of being constantly exposed to extreme temperatures, high pressures, and corrosive fluids. Engineers designing oilfield equipment systems know they need to make machinery that avoids costly downtime, extends service life, promotes operational safety, and improves recovery. This is why manufacturers trust Conventus to provide the best resin material for their components.

Conventus distributes several grades of the two premier structural thermoplastics used in the oilfield, which are polyetheretherketone (PEEK) and polyphenylene sulfide (PPS):

- PEEK – PEEK is commercially sold in a variety of grades, and Conventus offers a grade used to make oilfield gaskets with low warp capabilities. PEEK’s high strength, good strain capability, and excellent chemical resistance sets it apart and is the reason for its high desirability for many oilfield applications.

- PPS – PPS was the first structural thermoplastic to achieve commercial production and subsequent application in the industry as an engineering thermoplastic. Although the first versions to be commercially produced were low in molecular weight and designed to be used as coatings, further polymer manufacturing process improvements provided the pathway for broader application.

Interested in learning more about Conventus’ work in the oil and gas industry?

Contact us today to start a conversation!