Polymer Solutions for Your Industry

Conventus is highly focused in our strategic vertical markets. We keep an eye on the latest trends, the needs of our customers and of their markets, and marry those with the latest advancements in plastic technologies.

We are as equally invested in these vertical markets as our customers. By having an intimate understanding of our key markets, we are able to speak the same language as our customers when it comes to application performance requirements, regulatory requirements, and overall market challenges. It allows us to provide the very best material selection advice, formulate custom solutions, and even identify potential market disruptive solutions with the latest technology advancements before others. At Conventus we are known for proactively bringing these game-changing type of solutions to our customers in our strategic markets.

Some of our strategic vertical markets include:

Automotive / Transportation

Conventus offers a broad portfolio of resins and compounds for the ever-growing automotive and transportation industry.

More About Automotive / Transportation

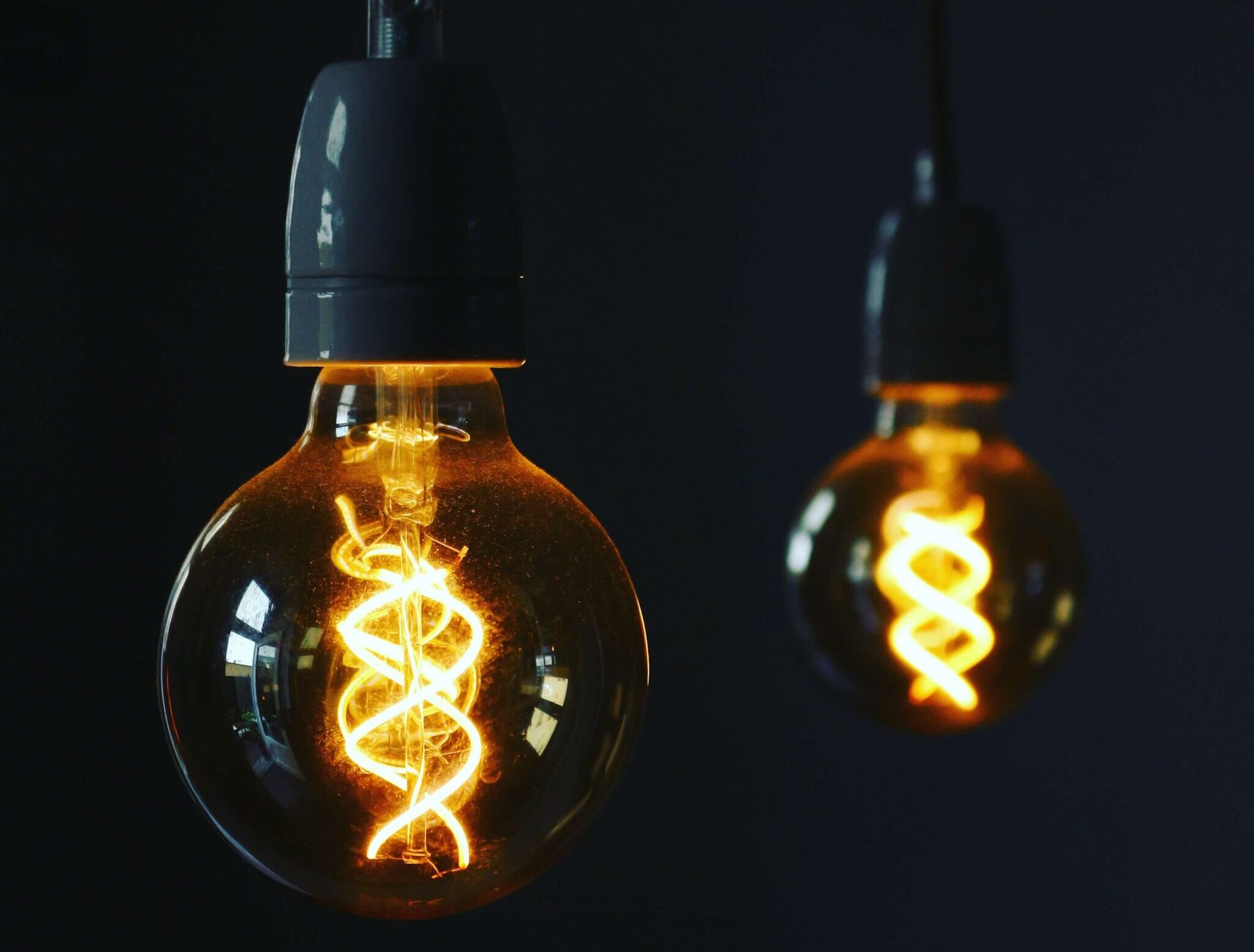

Electrical & Lighting

Products for electrical and lighting applications need to meet IEC, ISO, EN, and UL standards.

More About Electrical & Lighting

Energy Storage / EV

As EV becomes more popular, manufacturers will rely more heavily on quality plastic parts.

More About Energy Storage / EV

Healthcare

Conventus offers a large portfolio of ISO:10993 approved high-performance resins to manufacture medical devices to the most exact specifications.

More About Healthcare

Industrial

Parts for the industrial industry have stringent mechanical, thermal, and chemical standards.

More About Industrial

Membranes & Filtration

The team at Conventus works daily to develop components to complement membranes and filtration systems.

More About Membranes & Filtration

Oil & Gas

Equipment made for the oil and gas industry needs to withstand extreme temperatures, high pressures, and corrosive fluids.

More About Oil & Gas

Semiconductor

Production of semiconductors requires long-lasting, heavy-duty, clean components made from high-quality resin.

More About SemiconductorSporting Goods / Defense

Critical applications made with plastic components require ultra-high strength and super impact-resistant polymers.

More About Sporting Goods / Defense

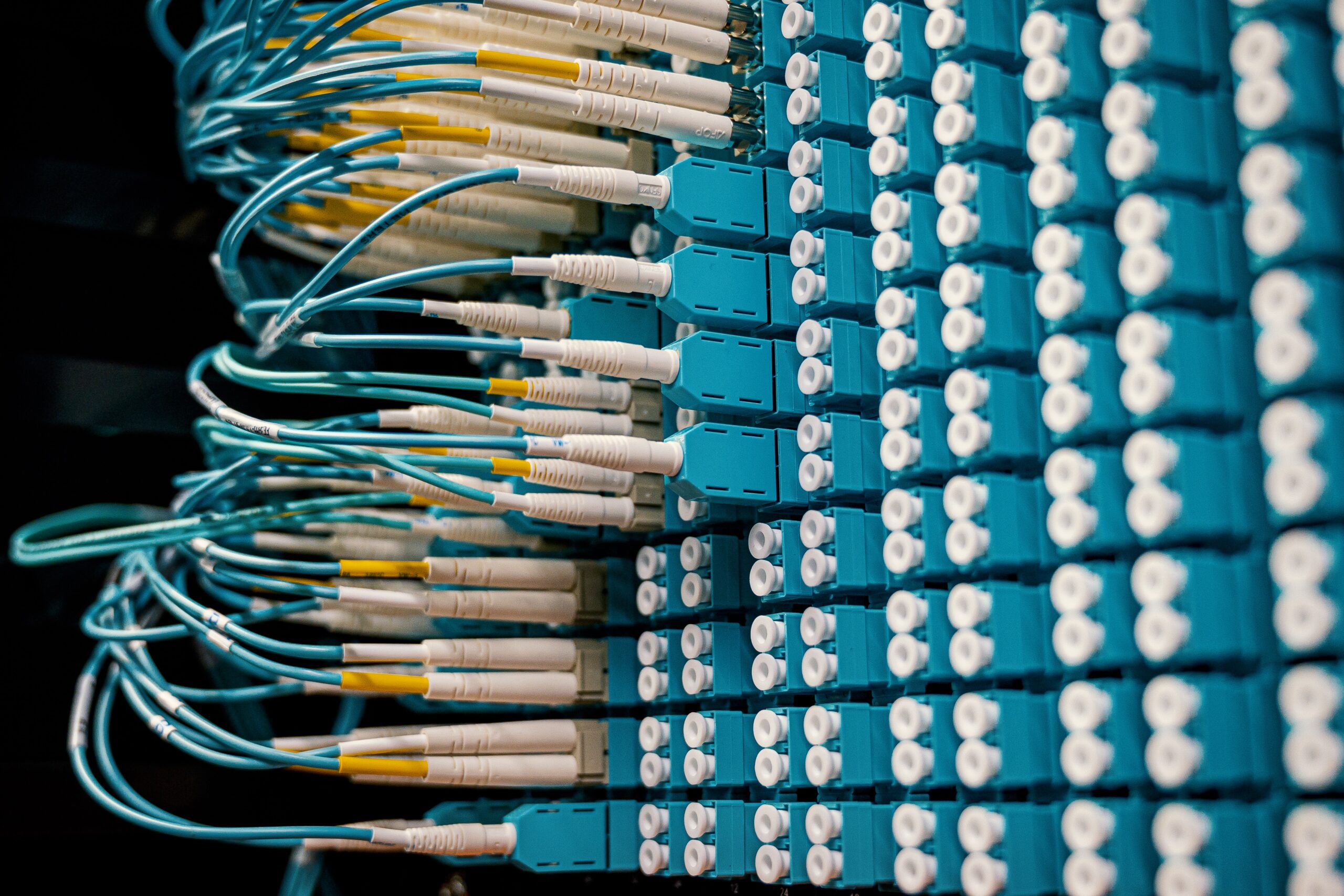

Telecomm / 5G

The telecommunications and 5G markets aren’t the wave of the future; they’re here now and more relevant than ever.

More About Telecomm / 5G

Water Management

Parts for plumbing applications need material considerations such as resistance to high temperatures, high pressures, and chemicals.

More About Water Management

Wire & Cable

Conventus has the most high-performance elastomers for insulation coating on wires and cables.

More About Wire & Cable